Officially launched the domestic Aurora Chery Jaguar Land Rover factory opened

Release Date:2017-12-27 Times of Browsing:2843

In October 21, 2014, the opening ceremony of Chery Jaguar Land Rover joint venture plant was held in Changshu, Jiangsu. Chery Jaguar Land Rover joint venture was founded in November 2012. After nearly 2 years of construction, the factory was officially opened today. It is reported that the plant has an annual capacity of 130 thousand units, and will be put into production in.

The aurora will appear at the Guangzhou auto show in November

There is little difference between the domestic aurora and the imported version. In the future, the aurora will be put into production in the factory. It is reported that the new car will be officially unveiled at the Guangzhou auto show in November. Rover aurora is Land Rover's medium-sized SUV, stylish fashion. From the look, we see the homemade version and the imported version of the same modeling, but on the right side of the tail attached to the logo of Chery Land Rover, showing the identity.

And the power assembly is still the same as the imported version of the 204PT, which is the 2.0T engine provided by Ford, which is consistent with the current import version. One of the advantages of this is that the 9AT transmission provided by ZF is used well along with the domestic version, which is the same as that of the imported version.

The new car will start at the Guangzhou auto show, which is opened in November. It does not mention the specific time of the market. Therefore, it is preliminarily presumed to be a formal sale at the beginning of next year. As for the price level, the possible start price is 400 thousand.

Brief introduction of Chery Jaguar Land Rover factory

Changshu factory covers an area of 1220 mu (811300 square meters), of which the building area is 376000 square meters.

Factory construction and equipment installation cost more than 5 million working hours, completing about 250000 meters piling operation, using more than 25000 tons of steel.

The annual capacity of the initial planning is 130000

The factory has a complete four major process of stamping, welding, coating, assembly, assembly and engine production. It has a quality center, a product trial center, and a product research and development center. It is one of the most advanced and efficient automotive manufacturing bases in the world.

Stamping shop: covering area: 36067 square meters, with two kinds of press lines: servo press line is the fastest production line in the world at present, up to 20SPM (1 parts per 3 seconds), to ensure energy saving and composite material performance; mechanical press line is the fastest mechanical press line at present in China, up to 15SPM (every 4 seconds production) A finished product) is a fully enclosed structure.

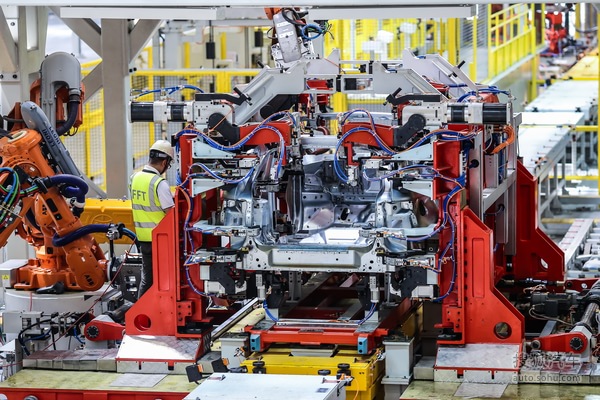

Welding workshop: Area: 72576 square meters, automation rate: 85%, spot welding adopts the most advanced intermediate frequency adaptive technology in the world. With 306 automatic robots, more than 85% of the welding work, covering more than 90% parts of the snatch and between the workspace, and all the body automatic sealing and coating, an average of 120 seconds to complete a car, the leading three-dimensional storage system: the largest automatic computer controlled three-dimensional body storage storage, 7 A total of 600 cars can be stored in a total of 5000 square meters, with the longest global reciprocating pole provided by the world's top suppliers and the collinear production of 3 different types of vehicles. The main tailor clamp can accommodate the flexible switching of 6 models, and the switching process can be completed in a beat time.

Center of quality: Area: 4320 square meters, three coordinates to check the size of the whole vehicle, 7 meters three arm three coordinates can be added to measure the chassis size, 14 meters three coordinates can be carried out at the same time a number of activities, Hydro-pulse shaking table and the environment bin, can simulate all season, all weather, all road conditions, comprehensive detection of vehicle noise, leaching rain, rain The test equipment can simulate the worst environment and use the industry leading air tightness test standard to carry out closed compression and pressure measurement. The 14 meter large CMM system is used to match the E-CUBE activity; the complete 3 axis CMM system is used for the whole vehicle measurement.

Assembly shop: floor area: 100000 square meters, using the most advanced integrated assembly mode at present in the world, in which the sliding column dynamic moving and positioning technology used in the assembly shop is the first one in China. The interior line adopts the form of lifting flat plate, and the human-computer engineering is realized by automation, and the flexibility is realized. Production, can accommodate 3 models, the use of advanced transport system, through the ANDON system, VCATS electronic module system, and radio frequency vehicle Traceability Technology, assembly workshop main line about 5000 kinds of technological lighting use the European brand LED energy saving lamp, compared with the General Factory T5 lighting, the annual energy saving about 30%.

【Chery Jaguar Land Rover vehicle production base】

In May 2014, Chery Jaguar Land Rover Motor Co., Ltd. (Chery Jaguar Land Rover) and Jaguar Land Rover China officially announced the joint establishment of a new joint market sales and service agency (IMSS), and appointed Lu Yi as the president of the joint agency. At the same time, it is understood that Chery and Jaguar Land Rover have reached a consensus on the issue of sales channels. In the future, imported cars and domestic cars will be sold in parallel.