|

isplay unit

|

Test pressure

|

kPa,Mpa、bar,PSI

|

|

Leakage

|

kPa

|

|

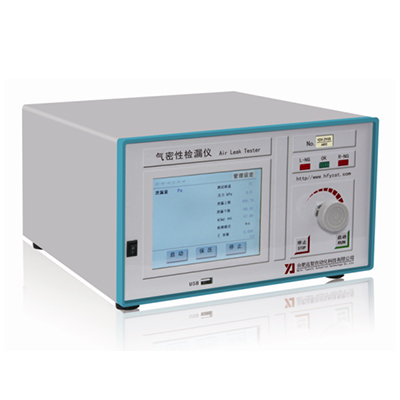

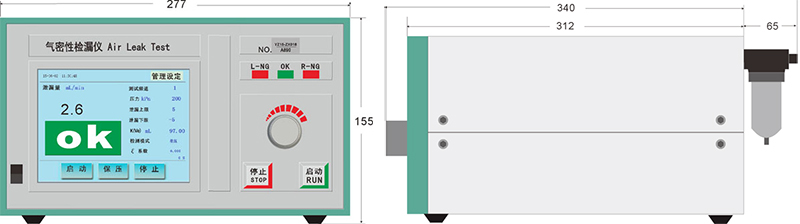

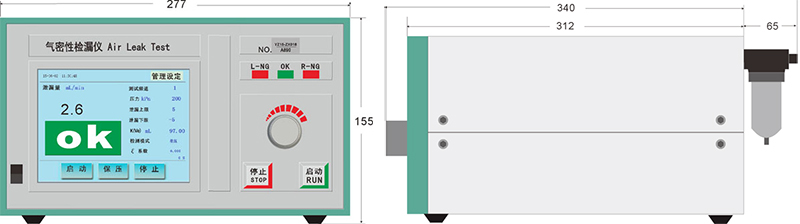

Mainframe

size

|

312(L)×277(W)×155(H) Footing12mm

|

|

Minimum display

|

1Pa

|

|

Display range

|

0~±1999.9Pa

|

|

Precision guarantee range

|

0~±2000Pa

|

|

Sensor range

|

0~±2000Pa

|

|

|

Test pressure range

|

500~-99kpa

|

|

Leakage volume display

|

The number of digits is 3, and the number of

decimal digits is 1.

|

|

Display sampling frequency 10HZ

|

|

|

|

Leaking

upper and lower limits

|

± 999.9Pa

|

|

Parameter channel number

|

32group(0~31)

|

|

Time setting

|

0~999s

|

|

Hardware

|

32bitCPU

|

|

Power Supply

|

AC220V±5%,50HZ

|

|

Test pressure source

|

Use vacuum pump to pump gas

|

|

ambient temperature

|

The temperature is 5~40 centigrade.

|

|

The preservation temperature is 0

~ 70 C

|

|

|

|

Humidity

|

80%RH, below, no condensation

|

|

Control the IO interface

|

Open circuit collector specification interface

and relay output

|

Note: the single side height of both sides screws is 2mm

5.4 inch touch screen display, the Chinese interface is clear and easy to understand.

It is convenient to analyze the detection process by checking the waveform.

The differential pressure resolution (1Pa) is of high precision.

Positive pressure multi-channel parameter "32 sets" can easily select and set parameter channels.

8 way output control, 8 way control input;

It has manual test mode and automatic test mode.

It has RS232 level output of serial port.

The remote control contacts are rich, can connect to PLC, and can directly drive external devices (such as cylinders, etc.).

The output terminals can be manually adjusted to make the external control more flexible.

The function of coating is that when the soapy water is used to soak the bubbles, the instrument remains in a state of keeping pressure.

The latest 10000 sets of test data can be saved, and the test results can be querying according to the date.

Leak detection result data, automatically stored;

Rich in data statistics and analysis functions;

With power-off memory protection

Quality analysis: Analyze and classify product quality by analyzing and categorizing the products tested

Leakage calculation: Simple and fast calculation of differential pressure leakage values and flow leakage values to help process and operators quickly calculate leak data.

Low voltage test: DC24V safe voltage

Additional charges are required:

Use U disk to export data function; export data to EXCEL, easy to edit on computer

Direct drive printer or wireless scanner (designated model)