Technical parameters of the LNKL series

Working pressure: inlet B: from vacuum up to 200 bar.

Operating pressure: inlet P1, P2: 6-12 bar compressed air.

Design: The main structural components are made of corrosion-resistant stainless steel and aluminum alloy; other designs can be made according to customer requirements.

Operating pressure: inlet P: 4 to 12 bar clean compressed air.

Seal: The main seal uses nitrile rubber. Urethane seals are available for wear-resistant applications.

Leakage rate: 10-3 mbar × l / s (10-4Pa × m3 / s)

*This is the minimum leakage rate of the standard; we can provide a lower leakage rate device on demand; depending on the detailed specifications (test method, test temperature and test pressure) provided by the customer and the quality of the sample supplied by the customer (ie sealing surface) Surface treatment conditions, roughness and dimensions allow tolerances).

Steps:

1. Press the handle to insert the quick connector into the thread to be tested;

2. Release the handle and the quick connector is connected.

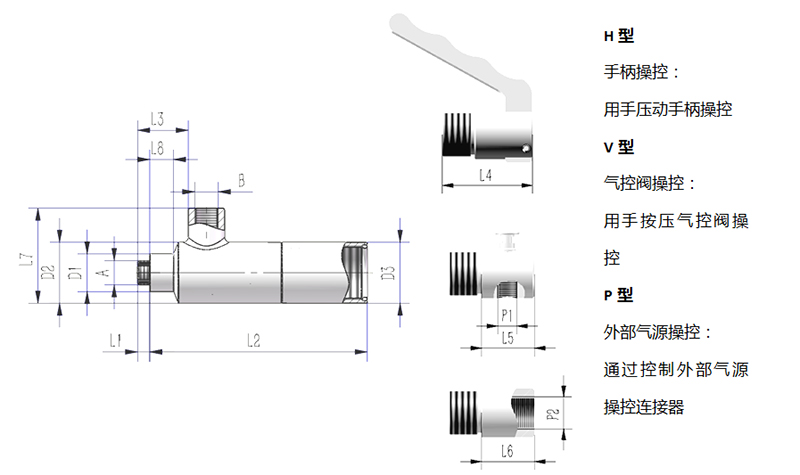

Operation form:

Standard sizes:

| Shape size | B1 | D1 | D2 | D3 | L1 | L2 | L3 | L4 | L5 | L6 |

| 1 | G 1/8" | 15.5 | 25 | 25 | 5.2 | 89.1 | 15.6 | 29.7 | 24 | 18 |

| 2 | G 1/4" | 19.5 | 27 | 27 | 6.5 | 89.6 | 13.6 | 30.7 | 18 | 18 |

| 3 | G 3/8" | 24 | 32 | 32 | 8 | 96.1 | 14.6 | 34 | 18 | 18 |

| 4 | G 1/2" | 30 | 36 | 36 | 9 | 99.5 | 14.3 | 35 | 18 | 18 |

| 5 | G3/4" | 33.1 | 43.5 | 36 | 9.7 | 136 | 16.2 | 36 | 18 | 18 |

| 6 | G3/4" | 37.7 | 49 | 36 | 9.7 | 136 | 16.2 | 36 | 18 | 18 |

| 7 | G1" | 41.7 | 49 | 36 | 12.7 | 136 | 11.7 | 36 | 18 | 18 |

| *Specification size is expressed in mm | ||||||||||

Metric ISO thread

Thread A

Shape size

Lmin*(mm)

Fast connector part number

Plugging part number

1

M10X0.75

9

LNKL-M200-01

LNKL-M200-01P

1

M10X1.0

9

LNKL-M200-02

LNKL-M200-02P

1

M10X1.25

9

LNKL-M200-03

LNKL-M200-03P

1

M10X1.5

9

LNKL-M200-04

LNKL-M200-04P

2

M12X1.0

10.5

LNKL-M201-01

LNKL-M201-01P

P

M12X1.25

10.5

LNKL-M201-02

LNKL-M201-02P

2

M12X1.5

10.5

LNKL-M201-03

LNKL-M201-03P

2

M12X1.75

10.5

LNKL-M201-04

LNKL-M201-04P

2

M14X1.0

10.5

LNKL-M202-01

LNKL-M202-01P

2

M14X1.5

10.5

LNKL-M202-02

LNKL-M202-02P

2

M14X2.0

10.5

LNKL-M202-03

LNKL-M202-03P

3

M16X1.0

11

LNKL-M203-01

LNKL-M203-01P

3

M16X1.5

11

LNKL-M203-02

LNKL-M203-02P

3

M16X2.0

11

LNKL-M203-03

LNKL-M203-03P

3

M18X1.0

11

LNKL-M204-01

LNKL-M204-01P

3

M18X1.5

11

LNKL-M204-02

LNKL-M204-02P

3

M18X2.0

11

LNKL-M204-03

LNKL-M204-03P

4

M20X1.0

12

LNKL-M205-01

LNKL-M205-01P

English straight pipe thread based on DIN ISO228-1 standard

Thread A| Shape size | Lmin*(mm) | Fast connector part number | Plugging part number | |

| 1 | G1/8” | 9 | LNKL-G100 | LNKL-G100P |

| 2 | G1/4” | 10.5 | LNKL-G101 | LNKL-G101P |

| 3 | G3/8” | 11 | LNKL-G102 | LNKL-G102P |

| 4 | G1/2” | 12 | LNKL-G103 | LNKL-G103P |

| 4 | G3/4” | 12 | LNKL-G105 | LNKL-G105P |

| 5 | G1” | 15 | LNKL-G106 | LNKL-G106P |

| *Lmin:Shortest thread length | ||||

BST (conical tube thread)

| Shape size | Thread A | Lmin*(mm) | Fast connector part number | Plugging part number |

| 1 | BSPT 1/8” | 9 | LNKL-B100 | LNKL-B100P |

| 2 | BSPT 1/4” | 10.5 | LNKL-B101 | LNKL-B101P |

| 3 | BSPT 3/8” | 11 | LNKL-B102 | LNKL-B102P |

| 4 | BSPT 1/2” | 12 | LNKL-B103 | LNKL-B103P |

| 4 | BSPT 3/4” | 12 | LNKL-B105 | LNKL-B105P |

| 5 | BSPT 1” | 15 | LNKL-B106 | LNKL-B106P |

| *Lmin:Shortest thread length | ||||

NPT- thread (according to the ANSI/ASME B 1.20-1983 standard)

| Shape size | Thread A | Lmin*(mm) | Fast connector part number | Plugging part number |

| 1 | NPT 1/8” | 9 | LNKL-N100 | LNKL-N100P |

| 2 | NPT 1/4” | 10.5 | LNKL-N101 | LNKL-N101P |

| 3 | NPT 3/8” | 11 | LNKL-N102 | LNKL-N102P |

| 4 | NPT 1/2” | 12 | LNKL-N103 | LNKL-N103P |

| 5 | NPT 3/4” | 15 | LNKL-N105 | LNKL-N105P |

| 6 | NPT 1” | 15 | LNKL-N106 | LNKL-N106P |

| *Lmin:Shortest thread length | ||||

Special type of LNKL series fast connector

Extended LNKL series fast connector is used for pressure test of limited internal thread parts in outer space, and can be customized according to customer's actual needs.