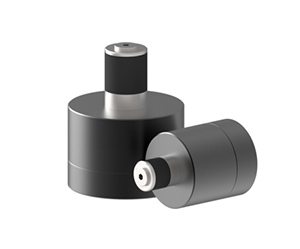

Technical parameters of KLN series

Working pressure: inlet B: from vacuum to up to 9 bar, other pressure ranges are available on request. When applied in a pressurized environment, the KLN series quick connector must be fixed by a fixture, only for vacuum applications. No fixture is required.

Operating pressure: inlet P: 4 to 12 bar clean compressed air.

Design: The housing, piston and washer are made of aluminum alloy.

Seal: The main seal uses an O-ring of nitrile rubber/chloroprene.

Urethane seals are available for wear-resistant applications.

Leakage rate: 10-3 mbar × l / s (10-4Pa × m3 / s)

*This is the standard minimum leak rate, we can provide lower leakage rate devices on demand, depending on the detailed specifications (test method, test temperature and test pressure) provided by the customer and the quality of the samples provided by the customer (ie sealing surface) Surface treatment conditions, roughness and dimensions allow tolerances).

Steps for usage:

1. Fix the quick connector with the fixing clamp, insert the KLN quick connector into the test piece, apply the control air source, connect the quick connector, and apply the test air source;

2. When disconnecting, always release the test pressure; release the control pressure and remove the quick connector.

Specification size (mm):

Dimensions Entrance B1 Drive port P1 Mounting port G ΦD2 ΦD1 L

1 M5 M5 M5 31.8 20.2 55.1

1 G1/8′′ G1/8′′ M6 39.9 25.9 64.7

2 G1/8′′ G1/8′′ M6 39.9 25.9 64.7

3 G1/8′′ G1/8′′ M6 60 40.6 77.5

4 G1/8′′ G1/8′′ M6 60 40.6 77.5

5 G1/2′′ G1/8′′ M6 88.6 58.7 93.5

6 G1/2′′ G1/8′′ M6 88.6 58.7 93.5

7 G3/4′′ G1/8′′ M6 106 76.2 108.2

8 G3/4′′ G1/8′′ M6 106 76.2 108.2

KLN series quick connector application

Leak test: pressure, underwater, helium test.

Other applications: filling, pressure and functional testing, and flushing.

Components: containers, plastic containers, medical components, valves, pumps, filters, pressure vessels and piping connections.

Special type of KLN series quick connector

If the standard type does not meet your requirements, we will provide you with a dedicated solution, welcome to consult.

| Shape size | Seal range A | Lmin*(mm) | KLN type | KLN type | Replace the seal | |

| (mm) | Part number | Plugging part number | Seal number | |||

| 1 | 7.7-8.3 | 12.2 | KLN01-0300 | KLN01-0300 P | 1 | KLN01-0300 NBR |

| 1 | 8.4-10.0 | 13.4 | KLN01-01 | KLN01-01 P | 1 | KLN01-01NBR |

| 1 | 10.0-11.0 | 15 | KLN1-11 | KLN1-11 P | 1 | KLN1-11 NBR |

| 1 | 11.0-12.0 | 15 | KLN1-12 | KLN1-12 P | 1 | KLN1-12 NBR |

| 1 | 12.0-13.0 | 15 | KLN1-13 | KLN1-13 P | 1 | KLN1-13 NBR |

| 1 | 13.0-14.0 | 15 | KLN1-14 | KLN1-14 P | 1 | KLN1-14 NBR |

| 1 | 14.0-15.0 | 15 | KLN1-15 | KLN1-15 P | 1 | KLN1-15 NBR |

| 1 | 15.0-16.0 | 15 | KLN1-16 | KLN1-16 P | 1 | KLN1-16 NBR |

| 2 | 16.0-17.0 | 15 | KLN2-21 | KLN2-21 P | 1 | KLN2-21 NBR |

| 2 | 17.0-18.0 | 15 | KLN2-22 | KLN2-22 P | 1 | KLN2-22 NBR |

| 2 | 18.0-19.0 | 15 | KLN2-23 | KLN2-23 P | 1 | KLN2-23 NBR |

| 2 | 19.0-20.0 | 15 | KLN2-24 | KLN2-24 P | 1 | KLN2-24 NBR |

| 2 | 20.0-21.0 | 15 | KLN2-25 | KLN2-25 P | 1 | KLN2-25 NBR |

| 2 | 21.0-22.0 | 15 | KLN2-26 | KLN2-26 P | 1 | KLN2-26 NBR |

| 3 | 22.0-23.5 | 27.8 | KLN3-31 | KLN3-31 P | 2 | KLN3-31 NBR |

| 3 | 23.5-25.0 | 27.8 | KLN3-32 | KLN3-32 P | 2 | KLN3-32 NBR |

| 3 | 25.0-26.5 | 27.8 | KLN3-33 | KLN3-33 P | 2 | KLN3-33 NBR |

| 3 | 26.5-28.0 | 27.8 | KLN3-34 | KLN3-34 P | 2 | KLN3-34 NBR |

| 4 | 28.0-30.0 | 27.8 | KLN4-41 | KLN4-41P | 2 | KLN4-41 NBR |

| 4 | 30.0-32.0 | 27.8 | KLN4-42 | KLN4-42P | 2 | KLN4-42 NBR |

| 4 | 32.0-34.0 | 27.8 | KLN4-43 | KLN4-43P | 2 | KLN4-43 NBR |

| 4 | 34.0-36.0 | 27.8 | KLN4-44 | KLN4-44P | 2 | KLN4-44 NBR |

| 5 | 36.0-38.0 | 40.9 | KLN5-51 | KLN5-51 P | 3 | KLN5-51 NBR |

| 5 | 38.0-40.0 | 40.9 | KLN5-52 | KLN5-52 P | 3 | KLN5-52 NBR |

| 5 | 40.0-42.0 | 40.9 | KLN5-53 | KLN5-53 P | 3 | KLN5-53 NBR |

| 5 | 42.0-44.0 | 40.9 | KLN5-54 | KLN5-54 P | 3 | KLN5-54 NBR |

| 6 | 44.0-46.0 | 41.4 | KLN6-61 | KLN6-61P | 3 | KLN6-61NBR |

| 6 | 46.0-48.0 | 41.4 | KLN6-62 | KLN6-62P | 3 | KLN6-62 NBR |

| 6 | 48.0-50.0 | 41.4 | KLN6-63 | KLN6-63P | 3 | KLN6-63 NBR |

| 6 | 50.0-52..0 | 41.4 | KLN6-64 | KLN6-64P | 3 | KLN6-64 NBR |

| 6 | 52.0-56.0 | 41.4 | KLN6-65 | KLN6-65P | 3 | KLN6-65 NBR |

| 7 | 56.0-59.0 | 41.4 | KLN7-71 | KLN7-71 P | 3 | KLN7-71 NBR |

| 7 | 59.0-62.0 | 41.4 | KLN7-72 | KLN7-72 P | 3 | KLN7-72 NBR |

| 7 | 62.0-65.0 | 41.4 | KLN7-73 | KLN7-73 P | 3 | KLN7-73 NBR |

| 8 | 65.0-69.0 | 41.4 | KLN8-81 | KLN8-81 P | 3 | KLN8-81 NBR |

| 8 | 69.0-72.0 | 41.4 | KLN8-82 | KLN8-82 P | 3 | KLN8-82 NBR |

| 8 | 72.0-75.0 | 41.4 | KLN8-83 | KLN8-83 P | 3 | KLN8-83 NBR |

| 8 | 75.0-78.0 | 41.4 | KLN8-84 | KLN8-84 P | 3 | KLN8-84 NBR |