configure

|

NO.

|

parts

|

brand

|

Remarks

|

|

1

|

5.4 touch color screen

|

远智

|

|

|

2

|

Self draining air source filter

|

SMC

|

|

|

3

|

Precision manual pressure regulating valve

|

SMC

|

|

|

4

|

Solenoid valve and electromagnetic valve seat

|

festo

|

|

|

5

|

High precision pressure transmitter

|

Emerson

|

|

|

6

|

Inflatable, balanced valve core

|

Germany

|

|

|

7

|

Leaking connector

|

festo

|

|

|

8

|

chip

|

32BIT core processor

|

|

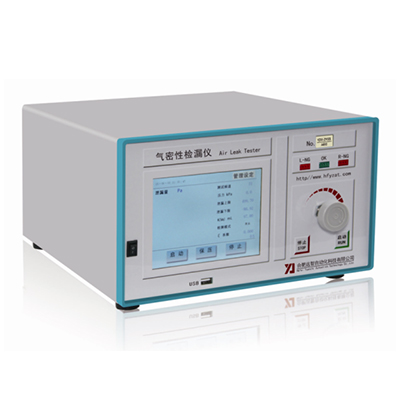

technical parameter

|

Display

unit

|

Test pressure

|

kPa,Mpa,PSI,bar,

|

|

Leakage

|

Pa,Pa/s,mL/min

|

|

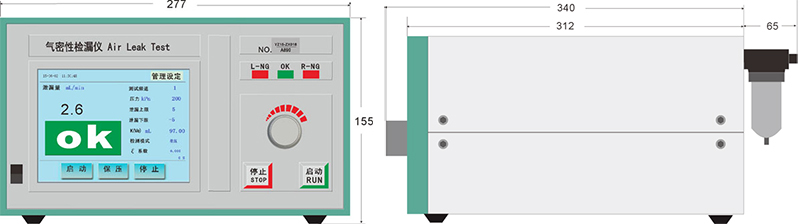

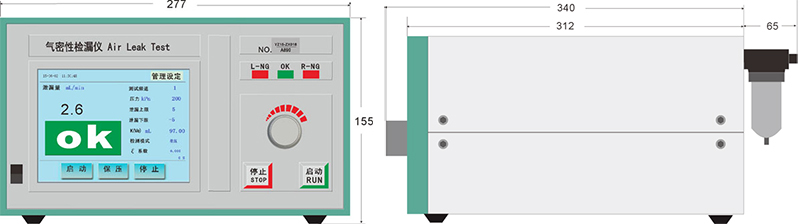

Mainframe size

|

312(L)×277(W)×155(H)

|

|

Precision range

|

±1%~±5%F.S

|

|

Minimum display

|

0.1Pa

|

|

Display range

|

0~±1999.9Pa

|

|

Precision guarantee range

|

0~±2000Pa

|

|

Sensor range

|

0~±2000Pa

|

|

Range of pressure measurement

|

5-100kPa

|

|

Pressure resistance of sensor

|

0.2MPa

|

|

Leakage volume display

|

The

number of integers is 3 bits, the mL decimal digit is 1 bits, and the sample

frequency 10HZ is displayed.

|

|

Leaking upper and lower limits

|

±1999.9Pa以下

|

|

Parameter channel number

|

32组(1-32)

|

|

Time setting

|

0~999秒

|

|

Hardware

|

32bitCPU

|

|

Test pressure source

|

In

general, dry clean air using 0.2~0.3MPa higher than the test pressure.

|

|

ambient temperature

|

The

temperature is 5~40 C and the storage temperature is 0~70 C.

|

|

Humidity

|

80%RH,

below, no condensation

|

|

Control the IO interface

|

Open

circuit collector specification interface and relay output

|

Note: the single side height of both sides screws is 2mm

5.4-inch touch screen display, Chinese operation interface is clear and easy to understand;

Check the waveform diagram to facilitate analysis of the inspection process;

Differential pressure resolution, high precision;

Multi-channel parameters, the parameter channel selection and setting can be easily performed;

8 output control, 8 control inputs;

With manual test mode and automatic test mode;

With serial RS232 level output;

The remote control contacts are rich, can be connected to the PLC, and can also directly drive external devices (such as cylinders);

The output terminals can be manually adjusted to make external control more flexible;

The bubble-coating function, that is, when the soapy water is soaked in water to visually detect the bubbles, the instrument maintains a pressure-holding state;

The latest 10000 sets of test data can be saved, and the test results can be queried by date;

Leak detection result data, automatically stored;

Rich in data statistics and analysis functions;

With power-off memory protection

Quality analysis: Analyze and classify product quality by analyzing and categorizing the products tested

Leakage calculation: Simple and fast calculation of differential pressure leakage values and flow leakage values to help process and operators quickly calculate leak data.

Low voltage test: DC24V safe voltage

Additional charges are required:

Use U disk to export data function; export data to EXCEL, easy to edit on computer

Direct drive printer or wireless scanner (designated model)